Table of ContentsShow

Attention all you power-hungry industrialists out there! Are you tired of being left in the dark (literally) because you bought the wrong DC-DC converter for your application? Don’t worry, we’ve got your back! In this article, we’re going to give you the inside scoop on the seven essential tips to consider when buying industrial switching regulators.

Whether you’re a seasoned pro or a newbie to the world of power supplies, these tips will help you make an informed decision and avoid any potential headaches. So buckle up and get ready to power up your industrial equipment and devices like a boss!

What is an Industrial DC-DC converter?

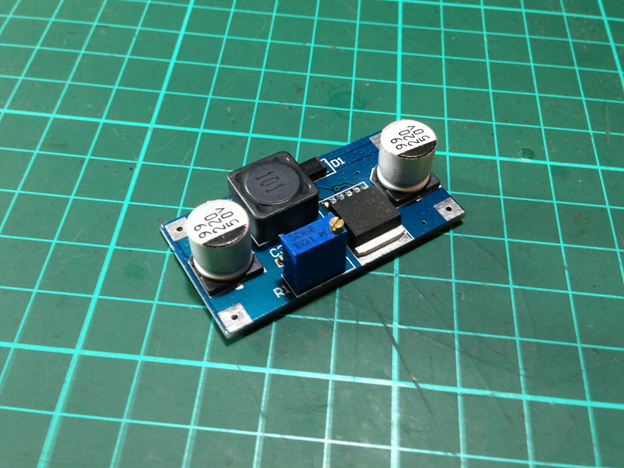

Industrial DC-DC converters convert DC input voltage to DC output voltage and are widely used in industries such as aerospace, automotive, telecommunications, and renewable energy. They can operate in a wide range of voltage levels and can convert various DC input voltages, making them useful in powering electronic devices.

DC-DC voltage regulators come in different forms and are designed to be efficient, reliable, and safe, with features such as overload protection, overvoltage protection, and over-temperature protection. Choosing the right converter requires considering factors such as topology, input/output voltage levels, and power rating.

Tips when Buying Industrial DC-DC Converters

Direct Current to Direct Current converters is indeed an essential part of many modern applications. They provide efficient power conversion between different voltage levels. Whether you’re working with renewable energy systems, motor drives, or industrial control systems, choosing the right equipment is critical to ensure the safe and reliable operation of your equipment.

Here are seven essential tips to consider when buying industrial DC-DC converters for your application:

1. Determine the Voltage Requirements of Your System

Before you start shopping for a DC-DC converter, it’s important to determine the voltage requirements of your system. Make sure you know the input and output voltage levels required by your equipment, as well as any other parameters such as current or power requirements. This will help you narrow down your options and ensure that you choose a converter that is compatible with your specific application.

For example, if you’re working with a 24V battery system and need to power a 12V motor, you’ll need a step-down Switching regulator that can convert the higher voltage to the lower voltage required by the motor.

2. Consider the Power Rating

Another important factor to consider when buying industrial DC-DC converters is the power rating. The power rating of a converter determines how much power it can handle and deliver to your equipment. You’ll want to choose a converter with a power rating that meets or exceeds the power requirements of your system.

For example, if you’re working with a motor that requires 100 watts of power, you’ll need a converter that can deliver at least 100 watts. Keep in mind that the power rating of a converter can be affected by factors such as the ambient temperature and airflow in your application, so it’s always a good idea to choose a converter with a higher power rating than you think you’ll need.

3. Look for Efficiency and Reliability

Efficiency and reliability are two critical factors to consider when buying industrial DC-DC converters. The efficiency of a converter determines how much of the input power is converted to the output power, and how much is lost as heat. Look for a converter with a high-efficiency rating, as this will help to reduce energy waste and heat generation in your system.

Reliability is also important, as a failure in your voltage regulator module can lead to costly downtime and repairs. Look for converters from reputable manufacturers with a proven track record of reliability, and consider factors such as operating temperature range, MTBF (mean time between failures), and protection features such as overvoltage, overcurrent, and short-circuit protection.

4. Consider the Size and Form Factor

The size and form factor of a converter are also important factors to consider, especially if you’re working with limited space or need to fit the converter into a specific enclosure or mounting location. Make sure you choose a converter that is small enough to fit into your application while still providing the required power output.

Some converters are available in different form factors, such as surface-mount or through-hole mounting, which can also affect their size and compatibility with your application.

5. Look for Customizable Options

Depending on your specific application, you may need a DC-DC converter with customized features or specifications. Look for manufacturers that offer customizable options, such as adjustable output voltage or current limits, that can be tailored to your specific requirements.

For example, if you’re working with a system that requires a variable output voltage, you’ll need a converter with an adjustable output voltage that can be tuned to the specific voltage levels required by your application.

6. Check for Compliance with Safety and Regulatory Standards

Industrial DC-DC converters are subject to various safety and regulatory standards, such as UL, CE, and RoHS. Make sure you choose a converter that is compliant with the relevant safety and regulatory standards in your region, as this will help to ensure the safe and reliable operation of your equipment and protect against potential legal or financial risks.

7. Consider the Total Cost of Ownership

Finally, when buying an industrial Voltage regulator module, it’s important to consider the total cost of ownership over the life of the converter. This includes not just the initial purchase price, but also factors such as energy efficiency, maintenance costs, and the lifespan of the converter.

A higher-priced converter with better efficiency and reliability may actually be more cost-effective in the long run than a cheaper converter that requires frequent repairs or has a shorter lifespan. Consider your budget and your long-term goals for your application when making your decision.

Conclusion

In summary, choosing the right industrial DC-DC converter for your application requires careful consideration of factors such as voltage requirements, power rating, efficiency, reliability, size and form factor, customizable options, safety and regulatory compliance, and total cost of ownership.

By taking these factors into account and doing your research, you can ensure that you choose a converter that meets your specific needs and provides reliable and efficient power conversion for your application.